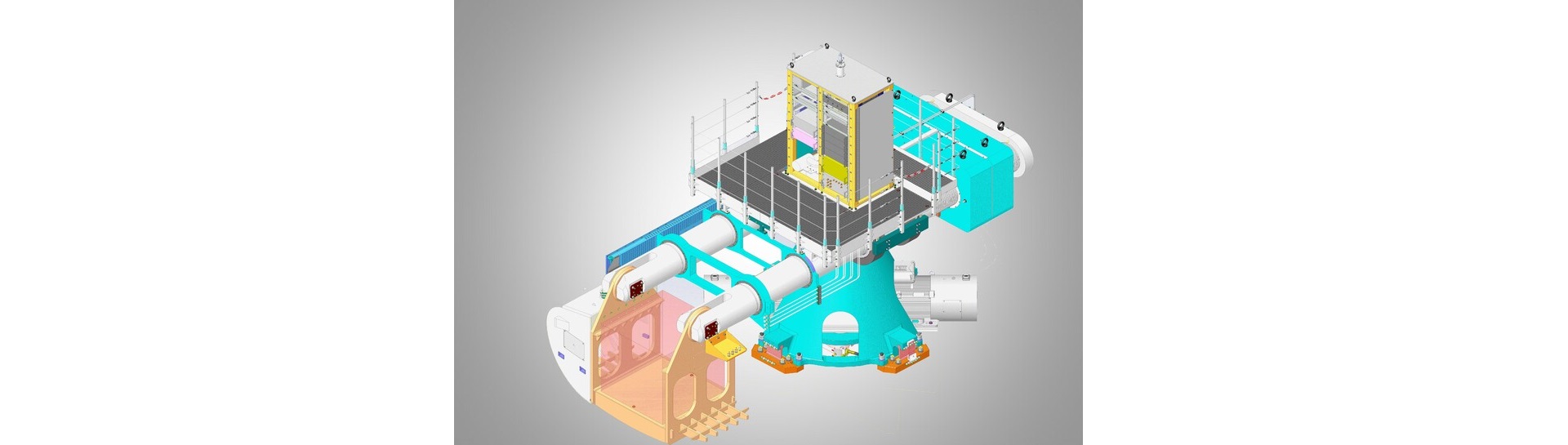

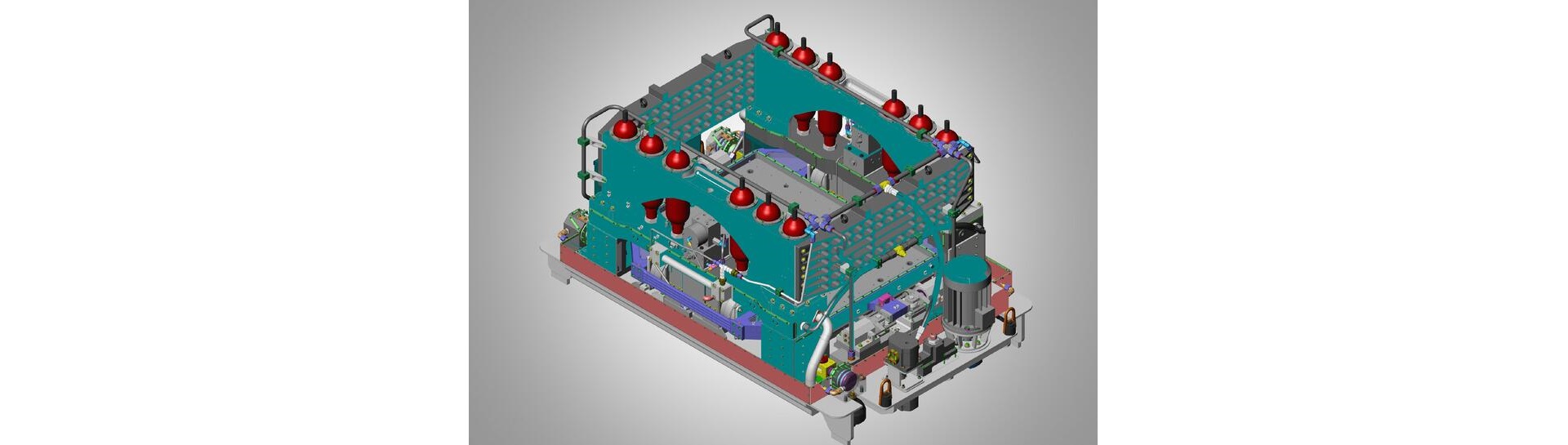

Your Actidyn cone penetrometer tool allows you to perform in-flight measurement tests of the penetration force of a cone head on all your foundation models. It is equipped with a moving mechanism allowing you to relocate the cone head in-flight without having to stop your centrifuge. The chosen location for the miniature strain gauge, immediately behind the cone head, eliminates any possible errors caused by the friction on the soil around the axis or caused by the drive mechanism and provides a reliable and precise measure of the penetration force.

Your Actidyn cone penetrometer tool system comes with a set of cone heads of different sizes to adapt to the specific needs of your application. Also the strain gauge can also be changed depending on the cone head size and its sensitivity can be adjusted to the level of the force to be measured.

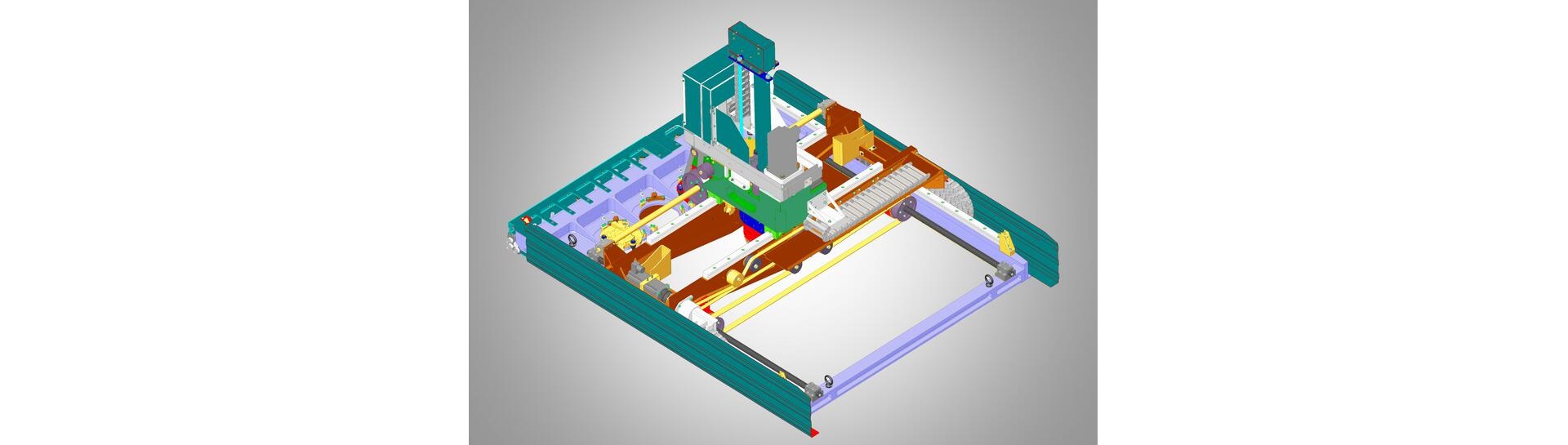

The moving mechanism is made of a rugged heavy-duty AC motor and a pinion transmission; the position read-out is derived from an LVDT. A resolver is attached to the drive mechanism ensuring a precise position read-out. The control system includes two industrial class numerical converters linked to a programmable controller.

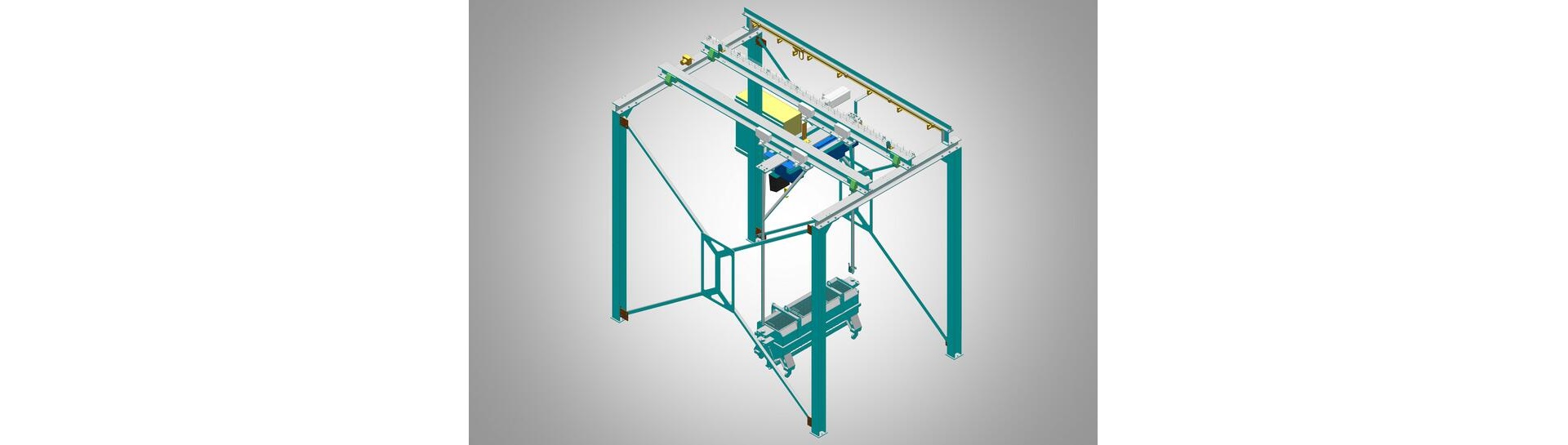

The control system is embarked aboard the centrifuge and transmist data to the controller via an ethernet hub and the centrifuge’s fiber optic rotary joint (FORJ). Work profiles and the user interface can be accessed from the control PC of the centrifuge (for last generation Actidyn centrifuges) or on a dedicated PC.

With your Actidyn cone penetrometer you can now perform reliable, precise and repeatable measurements, as well as other tasks such as inserting or removing instruments from your foundation model. Your in-flight Actidyn cone penetrometer can even allow you to displace objects and instruments from one location on your model to another. It opens up a whole new world of geotechnical possibilities with reliability and safety at a low cost.